3D LaserScan.

See your plant with new eyes.

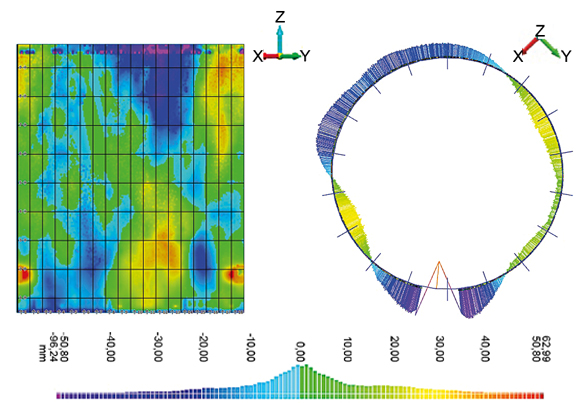

The 3D LaserScan-analysis sets new standards for the wear analysis, project planning and during any other phase of your repair.

Within a short period of time the 3D scanner will provide you with exact, three-dimensional pictures showing the condition of your plant. Together with our experts, you can now prioritise measures and adapt these to your time plan.

Discover the versatile possibilities and operating range of the 3D LaserScan during a

360° α-Check!

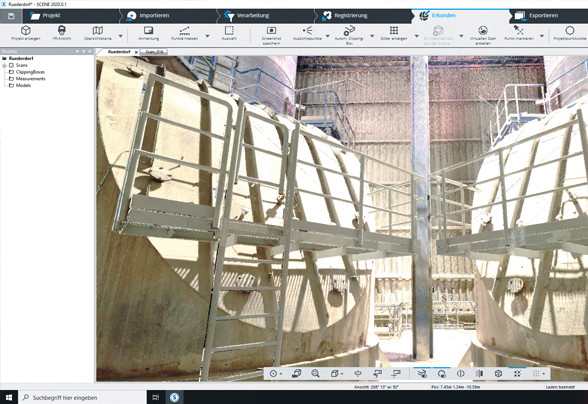

The 3D LaserScan registers the object up to a range of 70 m with an accuracy of 3 mm over 25 m. The resulting point cloud consists of millions of points with three-dimensional coordinates.

Furthermore, the surrounding is captured in high definition photographs for a photorealistic presentation, perfect for being the basis for repair planning, process optimization and 3D documentation.

Your advantages:

- Data to the exact millimetre – even from hardly accessible areas

- Pictures and data available within a short period of time

- No scaffolding necessary

- Determination of wear and remaining lining thickness possible

- Recording / analysis of structural changes to the statics

- Detailed analysis / target-actual comparison

- Precise definition of necessary measures

- Operating range: from repair preparation to sustainable process optimization

- Optional: annual readings enable prognosis about life cycle, maintenance cycles and predictive maintenance

- Safety plus: no personnel in the risk area